Fin Condenser

Laser Condenser Manufacturers

In case you do not find the type or model in the website

We can customized according to your request.

Contact Now

Contact Now

- TEL:0086-21-35324169

- FAX:0086-21-35324166

- Email:sales@shenglintec.com

- WhatsApp:0086 13916147965

- Mob:0086 13916147965

Material:

Tube: 3/8" stainless steel.

Fin: copper.

Fan plate: aluminum.

It is ideal for applications where deionized water or corrosive fluids are used, and a high efficiency, compact unit is required.

About Shenglin:

About Shenglin:

Shenglin is a leading design and manufacturing company specialized in Tube Fin Heat Exchangers.

Our skilled engineers utilize Italy's state-of-the-art Mcoil thermal calculation software to create high-quality heat exchangers. Their expertise enables us to produce accurate drawings and performance calculation documents.

In terms of production, our advanced facilities house multiple dedicated production lines for finned tube heat exchangers.

Our sheet metal production lines are equipped with cutting-edge laser cutting machines, CNC punch presses, CNC bending machines, and stretching hydraulic devices for guide rings. Furthermore, our tube-expanding equipment includes both mechanical and hydraulic tube expanders. Shenglin utilizes gas welding and argon arc welding methods, as well as offering spray coating and electrophoretic processes to meet the unique requirements of our customers.

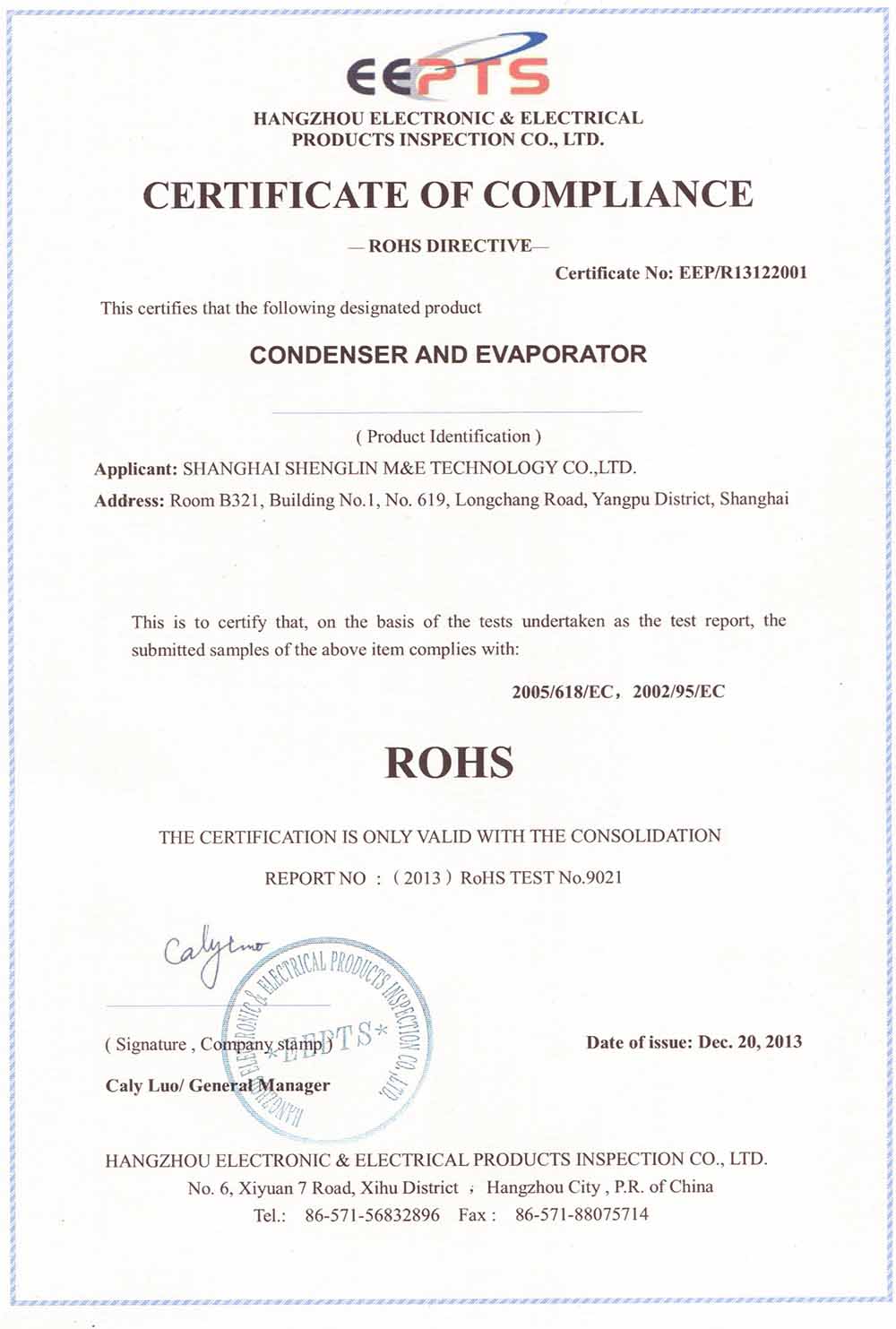

Quality is paramount at Shenglin. Our Tube Fin Heat Exchangers adhere to the highest standards and carry international certifications such as Rohs, CE, and UL, which are widely recognized worldwide.

Quality is paramount at Shenglin. Our Tube Fin Heat Exchangers adhere to the highest standards and carry international certifications such as Rohs, CE, and UL, which are widely recognized worldwide.

Equal to Lytron 4000 Series highest performing stainless steel tube-fin heat exchangers, ideal for applications where deionized water or corrosive fluids are used and a high efficiency, compact unit is required.

When high performance in a small envelope is required, the Lytron 4000 Series is the best option. Heavy-walled, seamless stainless steel tubes are expanded into copper fin with an extruded full collar. The copper fin and the excellent metal-to-metal contact between the tube and the fin collar ensure optimum thermal performance.

All wetted surfaces are 316L stainless steel, making them ideal for high purity and/or corrosive coolants such as deionized water. The welded stainless steel frame and fan plate offer durability and strength.

Equal to Lytron 4000 Series heat exchangers, the wall thickness is 0.7 mm, and are 100% leak tested to 10.3 bar. The integrated fan plate acts as a plenum to ensure uniform air-flow distribution through the core, thus maximizing performance. It also enables easy fan installation.

4000 Series style heat exchangers can be manufactured in custom sizes and tube configurations to meet your thermal and mechanical specifications. Inlet/outlet positions, fittings, paints and other coatings are available. Assemblies including fans and other components can also be supplied.

Heat exchanger for South Korea laser machine factory:

Radiator for Spain laser machine factory:

Radiator for Spain laser machine factory:

Military & Aerospace; Medical; Industrial; Lasers; Medical Imaging; Analytical Instrumentation; Power Electronics; Semiconductor Equipment; Machine Tools; Telecommunications

anterior:Huge Condenser Coils

+Newsmore

- 01 Feb,2024Dry Cooler D4-8x910 In Stock Is On Sale! Discount!

- 06 Sep,2023Pad Adiabatic Dry Cooler Trial Operation Before Shipment

- 06 Sep,2023828kW Adiabatic Cooling System Dry Cooler Loading

- 17 Aug,2022Flat Type Dry Cooler Finished For Canada Client

- 06 Sep,20231061kW dry cooler loading for USA client

- 31 Mar,2021Peru client Install Shenglin Adiabatic Dry Cooler At Site