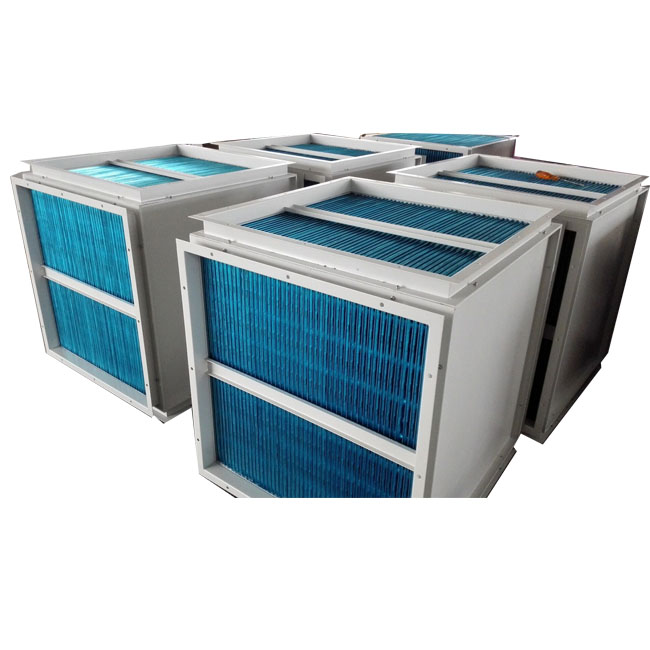

Cross Flow Heat Exchanger

Total 1 página 18 archivos

Application:

Solution:

1. Waste heat recovery equipment energy saving solution:

1. Waste heat recovery equipment energy saving solution, please click here

2.Printing waste heat recovery energy saving solution,please click here

Solution:

1. Waste heat recovery equipment energy saving solution:

A. Equipment introduction:

The HRV-F waste heat recovery equipment exchanges heat between the high-temperature exhaust gas and the fresh air through the heat exchange core, preheats the fresh air with high temperature of the exhaust gas, improves the temperature of the incoming air, and can also dry the original and auxiliary materials to achieve the purpose of energy recovery. .

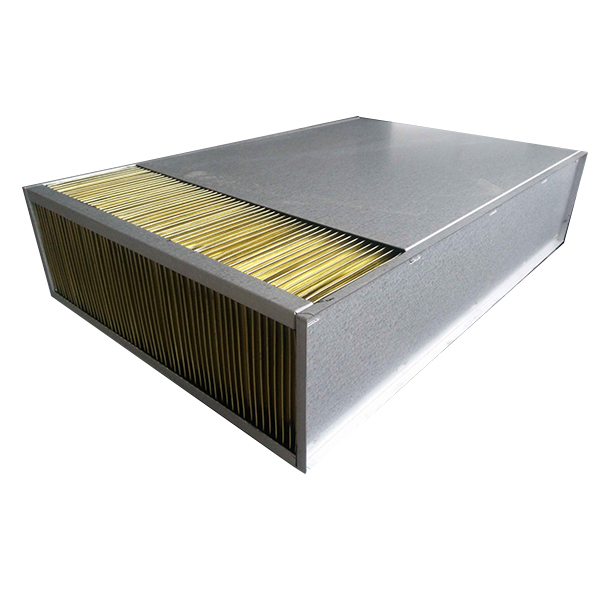

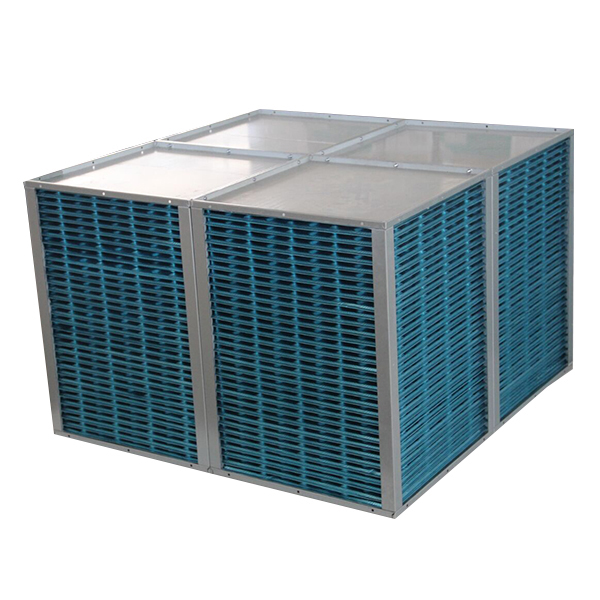

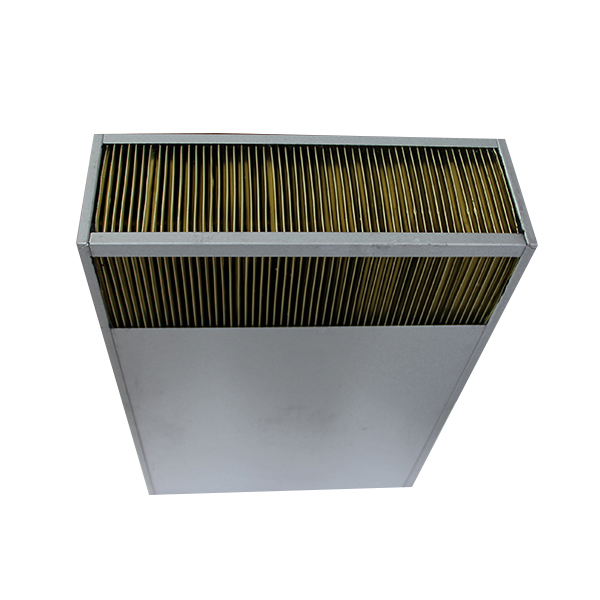

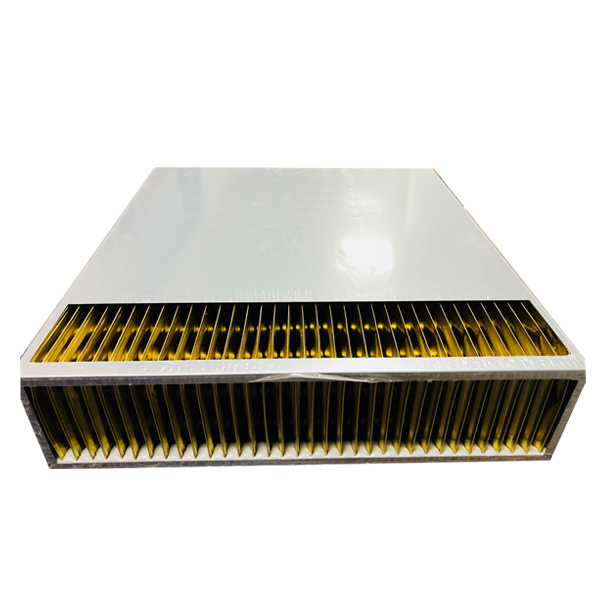

Built-in cross-flow static heat exchange core, that is, the direction of movement of cold and hot gases is perpendicular to each other, heat exchange is realized in the process of air flowing on the flat plate, high heat exchange rate can be achieved, no moving parts, high reliability, The air mixing rate is low. The core is mainly made of hydrophilic aluminum foil material, adopts a unique point-to-face combination sealing process, has long service life and high temperature conductivity, does not cause penetration, and does not cause secondary pollution due to the penetration of exhaust gas; The inner and outer surfaces are treated by electrostatic spray, which plays a very good role in rust prevention.

Hydrophilic aluminum foil heat exchanger Epoxy resin aluminum foil heat exchanger Stainless steel foil heat exchanger

E. Application process of heat recovery equipment (take drying process as an example):

B. Applicable environment:

Combustion chamber, waste heat utilization of power station, tail gas utilization of dryer, waste heat recovery of printing and dyeing (textile industry, plastics industry); ventilation of food drying, vegetables, tobacco leaves, seeds, herbs, dried fruits, seafood, food, etc.; Waste heat recovery in kaolin spray drying hot blast stove; waste heat recovery in glass kiln; waste heat recovery in cement kiln; waste heat recovery in various ceramic deflagration furnaces and tunnel kiln; metal painting spray drying, molding materials Dry and so on. It is intended to improve the working efficiency of drying equipment, energy saving, environmental protection and quality assurance.

C. Working principle:

C. Working principle:

The device adopts a stationary cross-flow heat exchange core body, and the core body is made of a hydrophilic aluminum foil as a carrier, and is composed of several layers of heat exchange unit bodies, and the flow paths of the fluids of the adjacent two-layer unit bodies are arranged in a positive cross, and the principle is the high temperature introduced. Exhaust gas and fresh air flow through the heat exchange core in a positively intersecting manner. Heat is transferred from the high temperature side to the low temperature side through the heat transfer partition to exchange heat, and the fresh air after heat exchange becomes hot air and then sent to the required place.

D. Features:

The high-efficiency energy-saving heat exchanger adopts high-quality hydrophilic coated aluminum foil which is resistant to seawater corrosion as a heat transfer conductor. It is processed by a special process to fully recover the high heat in the exhaust gas. No additional energy is required except the fan, and the comprehensive energy saving can reach more than 50%. . Epoxy aluminum foil or stainless steel foil can also be used, which is more resistant to corrosion and suitable for special occasions.

Completely isolated The heat exchanger's fresh air and exhaust air passages intersect with aluminum foil, and the entry and exit edges feature five-layer crimping for higher edge strength and more reliable sealing.

High stability No moving parts, low equipment maintenance costs, high reliability and long service life.

Low maintenance cost, compact size, easy installation and maintenance, direct cleaning with tap water or neutral detergent, daily maintenance intensity is small, and maintenance costs are low. The original exhaust fan can be used, and the equipment input and running cost are low.

Wide applicability The modular construction provides a combination of edge length and plate overlay thickness of any size. The design can be changed according to the customer's needs, such as shape, installation method, and air outlet interface position. Different materials and special treatments can be designed for the heat recovery equipment casing according to the customer's environment.

Hydrophilic aluminum foil heat exchanger Epoxy resin aluminum foil heat exchanger Stainless steel foil heat exchanger

E. Application process of heat recovery equipment (take drying process as an example):

When the drying box is baking materials, it is necessary to continuously add fresh air to discharge the moisture and odor of the materials to achieve drying of the materials. The fresh air that is generally added is normal temperature air, which is consistent with the environmental conditions. The conventional drying process requires the heating device to consume a large amount of energy to heat the normal temperature air to the required temperature of the drying box.

The drying process with heat recovery equipment, the heat recovery equipment can preheat the fresh air at room temperature by using the high temperature energy of the exhaust air, and the high temperature and high humidity air (wet heat exhaust air) discharged from the drying box is discharged through the heat exchanger before being discharged. At normal temperature, the fresh air is first sent to the drying room through the heat exchange core. The two airs exchange heat in the heat exchanger. Since the two airs are completely isolated, the exhausted air will not be mixed into the fresh air, and the fresh air absorbs the heat of the exhaust. The temperature will rise sharply, and the temperature will also drop after the exhaust air is exchanged with the fresh air heat, and then discharged to the outdoor environment. As a result, the temperature of the fresh air is significantly increased after heat exchange, and the fresh air is heated by the heating device, which can greatly reduce the energy consumption for heating the fresh air to the required temperature of the drying box.

1. Waste heat recovery equipment energy saving solution, please click here

2.Printing waste heat recovery energy saving solution,please click here

+Newsmore

- 01 Feb,2024Dry Cooler D4-8x910 In Stock Is On Sale! Discount!

- 06 Sep,2023Pad Adiabatic Dry Cooler Trial Operation Before Shipment

- 06 Sep,2023828kW Adiabatic Cooling System Dry Cooler Loading

- 17 Aug,2022Flat Type Dry Cooler Finished For Canada Client

- 06 Sep,20231061kW dry cooler loading for USA client

- 31 Mar,2021Peru client Install Shenglin Adiabatic Dry Cooler At Site