Water Cooled Chiller For Plastic Industry

Contact Now

- TEL:0086-21-35324169

- FAX:0086-21-35324166

- Email:sales@shenglintec.com

- WhatsApp:0086 13916147965

- Mob:0086 13916147965

|

SW- |

|||||||||||

|

Type |

100S |

135S |

175S |

190S |

235S |

260S |

300S |

320S |

350S |

380S |

|

|

Nominal cooling capacity |

kw |

98.0 |

135.0 |

175.6 |

191.1 |

233.3 |

255.6 |

301.1 |

317.8 |

347.8 |

380.0 |

|

104 kcal/h |

8.4 |

11.6 |

15.1 |

16.4 |

20.1 |

22.0 |

25.9 |

27.3 |

29.9 |

32.7 |

|

|

Operating control method |

Use PLC microcomputer control |

||||||||||

|

Power Supply |

380V/3N/50HZ |

||||||||||

|

Startup type |

Y-△ |

||||||||||

|

Compressor |

Type |

Semi-closed 5:6 asymmetric twin-screw compressor |

|||||||||

|

Input power(kw) |

23.0 |

30.0 |

39.0 |

42.0 |

51.0 |

56.0 |

63.0 |

66.0 |

73.0 |

80.0 |

|

|

Rated current(A) |

39.2 |

51.6 |

64.7 |

71.0 |

86.4 |

94.1 |

105.9 |

111.4 |

122.7 |

133.8 |

|

|

Energy regulation |

0-33%-66%-100% |

0-25%-50%-75%-100% |

|||||||||

|

Evaporator |

Type |

High efficiency dry type shell and tube heat exchanger |

|||||||||

|

Flow(m3/h) |

16.9 |

23.2 |

30.2 |

32.9 |

40.1 |

44.0 |

51.8 |

54.7 |

59.8 |

65.4 |

|

|

Water pressure drop(kPa) |

45.0 |

45.0 |

48.0 |

48.0 |

50.0 |

50.0 |

50.0 |

55.0 |

55.0 |

55.0 |

|

|

Interface size |

DN65 |

DN80 |

DN100 |

DN125 |

|||||||

|

Condenser |

Type |

High efficiency shell and tube heat exchanger |

|||||||||

|

Flow(m3/h) |

20.8 |

28.4 |

36.9 |

40.1 |

48.9 |

53.6 |

62.6 |

66.0 |

72.4 |

79.1 |

|

|

Water pressure drop(kPa) |

42.0 |

42.0 |

45.0 |

45.0 |

48.0 |

48.0 |

48.0 |

52.0 |

52.0 |

52.0 |

|

|

Interface size |

DN65 |

DN80 |

DN100 |

DN125 |

|||||||

|

Refrigerant |

Type |

R22 |

|||||||||

|

Refrigerant volume(kg) |

20.0 |

25.0 |

32.0 |

35.0 |

40.0 |

46.0 |

53.0 |

55.0 |

60.0 |

65.0 |

|

|

Overall dimensions |

Length(mm) |

2310 |

2350 |

2420 |

2690 |

2690 |

2690 |

3080 |

3080 |

3080 |

3080 |

|

Width(mm) |

660 |

660 |

660 |

810 |

840 |

890 |

920 |

935 |

935 |

935 |

|

|

Height(mm) |

1520 |

1550 |

1590 |

1600 |

1660 |

1660 |

1710 |

1710 |

1750 |

1750 |

|

|

Weight |

Machine weight(kg) |

850 |

1050 |

1150 |

1270 |

1340 |

1430 |

1640 |

1710 |

1780 |

1850 |

|

Operating weight(kG) |

900 |

1150 |

1300 |

1420 |

1540 |

1670 |

1890 |

1930 |

1970 |

2050 |

|

|

SW- |

|||||||||||

|

Type |

415S |

495S |

520S |

570S |

620S |

640S |

740S |

820S |

870S |

980S |

|

|

Nominal cooling capacity |

kw |

415.0 |

495.0 |

521.1 |

571.1 |

617.8 |

642.2 |

741.8 |

821.1 |

871.7 |

981.8 |

|

104 kcal/h |

35.7 |

42.6 |

44.8 |

49.1 |

53.1 |

55.2 |

63.8 |

70.6 |

74.9 |

84.4 |

|

|

Operating control method |

Use PLC microcomputer control |

||||||||||

|

Power Supply |

380V/3N/50HZ |

||||||||||

|

Startup type |

Y-△ |

||||||||||

|

Compressor |

Type |

Semi-closed 5:6 asymmetric twin-screw compressor |

|||||||||

|

Input power(kw) |

88.0 |

103.0 |

108.0 |

118.0 |

126.0 |

130.0 |

150.0 |

167.0 |

177.0 |

199.0 |

|

|

Rated current(A) |

148.8 |

172.8 |

182.5 |

197.7 |

212.8 |

219.6 |

253.0 |

280.7 |

298.1 |

335.2 |

|

|

Energy regulation |

0-25%-50%-75%-100% |

||||||||||

|

Evaporator |

Type |

High efficiency dry type shell and tube heat exchanger |

|||||||||

|

Flow(m3/h) |

71.4 |

85.1 |

89.6 |

98.2 |

106.3 |

110.5 |

128.6 |

141.2 |

150.8 |

169.9 |

|

|

Water pressure drop(kPa) |

55.0 |

58.0 |

62.0 |

62.0 |

68.0 |

68.0 |

68.0 |

70.0 |

70.0 |

72.0 |

|

|

Interface size |

DN125 |

DN150 |

DN200 |

||||||||

|

Condenser |

Type |

High efficiency shell and tube heat exchanger |

|||||||||

|

Flow(m3/h) |

86.5 |

102.9 |

108.2 |

118.5 |

127.9 |

132.8 |

154.4 |

170.0 |

181.2 |

204.1 |

|

|

Water pressure drop(kPa) |

55.0 |

56.0 |

58.0 |

60.0 |

65.0 |

65.0 |

65.0 |

68.0 |

68.0 |

70.0 |

|

|

Interface size |

DN125 |

DN150 |

DN200 |

||||||||

|

Refrigerant |

Type |

R22 |

|||||||||

|

Refrigerant volume(kg) |

70.0 |

85.0 |

90.0 |

100.0 |

110.0 |

120.0 |

140.0 |

165.0 |

170.0 |

155.0 |

|

|

Overall dimensions |

Length(mm) |

3110 |

3340 |

3440 |

3440 |

3440 |

3440 |

3550 |

3550 |

3550 |

3550 |

|

Width(mm) |

995 |

995 |

1000 |

1000 |

1080 |

1280 |

1280 |

1310 |

1310 |

1325 |

|

|

Height(mm) |

1870 |

1930 |

2020 |

2020 |

2020 |

2090 |

2090 |

2240 |

2240 |

2270 |

|

|

Weight |

Machine weight(kg) |

2080 |

2300 |

2570 |

2850 |

2900 |

3100 |

3450 |

4050 |

4230 |

4450 |

|

Operating weight(kG) |

2330 |

2550 |

2950 |

3000 |

3200 |

3450 |

3750 |

4450 |

4600 |

4850 |

|

Cooling condition: Chilled water inlet/outlet temperature 12/7 ℃, cooling water inlet/outlet temperature 30℃/35℃

Temperature term: Chilled water outlet temperature 5℃~15℃; cooling water inlet temperature 19℃~33℃.

Cooling the hot plastic that is injected, blown, extruded or stamped. (There are many types of plastics applications) Injection molding chillers are the most common name for such an application.

Recommend products:

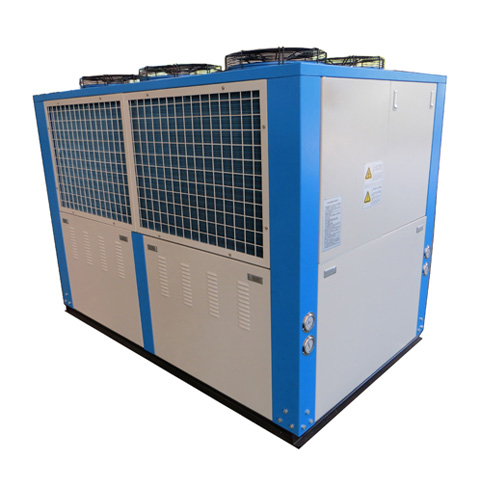

Usually cooling tower offers chilled water to water cooled chiller, here we recommend our dry cooler to instead of cooling tower.

| Structure Type | Model | Photo | Cooling cpacity (kw) | Air volume (m3/h) | Fan Diameter(mm) | Air discharge direction | Key documents |

|---|---|---|---|---|---|---|---|

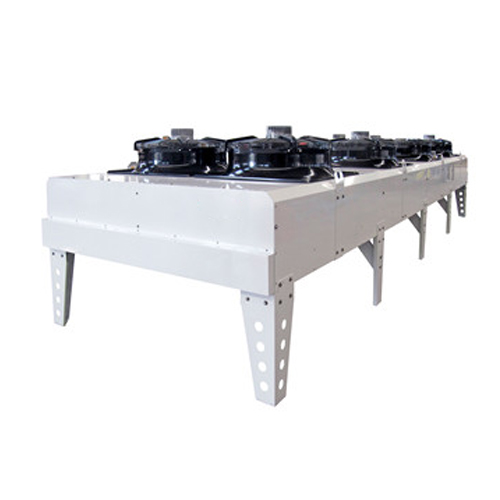

| Plate Type | D1-005-1x350~D1-649-16x630 |

|

5~649 | 2828~263503 | 350~630 | Vertical | Brochure of D1 |

|

Horizontal | ||||||

| V type | D2-148-4X630~D2-921-20x630 |

|

148~921 | 76459~351663 | 630 | Vertical | Brochure of D2 |

| Plate Type | D3-042-1X800~D3-607-12X800 |

|

42~607 | 21454~227449 | 800 | Vertical | Brochure of D3 |

| V type | D4-176-4X800~D4-792-16X800 |

|

176~792 | 21454~227449 | 800 | Vertical |

Brochure of D4 |

|

No. |

Name |

Brand |

Original |

|

1 |

Compressor |

Hanbell |

Taiwan |

|

2 |

PLC computer controller |

SIEMENS |

Germany |

|

3 |

AC contactor |

LG |

Korea |

|

Thermal relay |

LG |

Korea |

|

|

Power protector |

CARLO |

Swiss |

|

|

4 |

Heat exchanger |

HENGDA/LENGDE |

China |

|

Sight glass |

ENERSON |

USA |

|

|

Expansion valve |

ENERSON |

USA |

|

|

High and low pressure gauge |

GYPG |

China |

|

|

Flow switch |

KAOBO |

China |

|

Country: Bolivia |

Country: Philippines |

Country: Malaysia |

Country: UAE |

|

|

|

|

|

- 01 Feb,2024Dry Cooler D4-8x910 In Stock Is On Sale! Discount!

- 06 Sep,2023Pad Adiabatic Dry Cooler Trial Operation Before Shipment

- 06 Sep,2023828kW Adiabatic Cooling System Dry Cooler Loading

- 17 Aug,2022Flat Type Dry Cooler Finished For Canada Client

- 06 Sep,20231061kW dry cooler loading for USA client

- 31 Mar,2021Peru client Install Shenglin Adiabatic Dry Cooler At Site