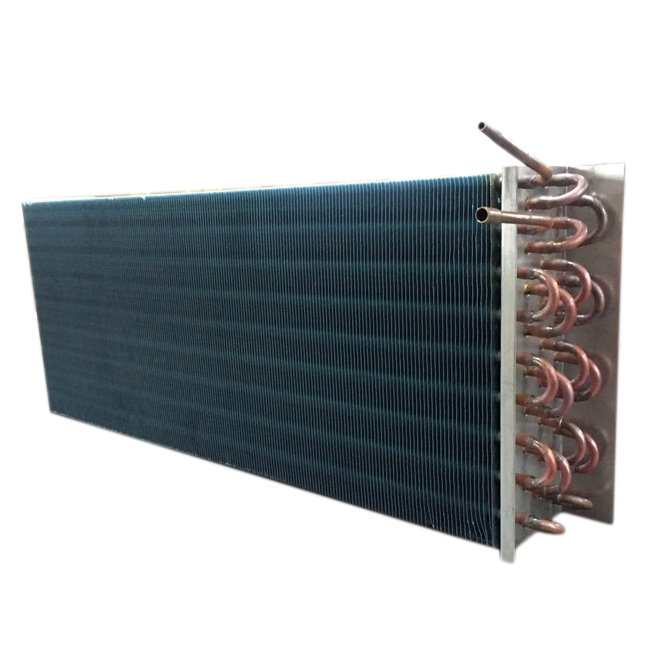

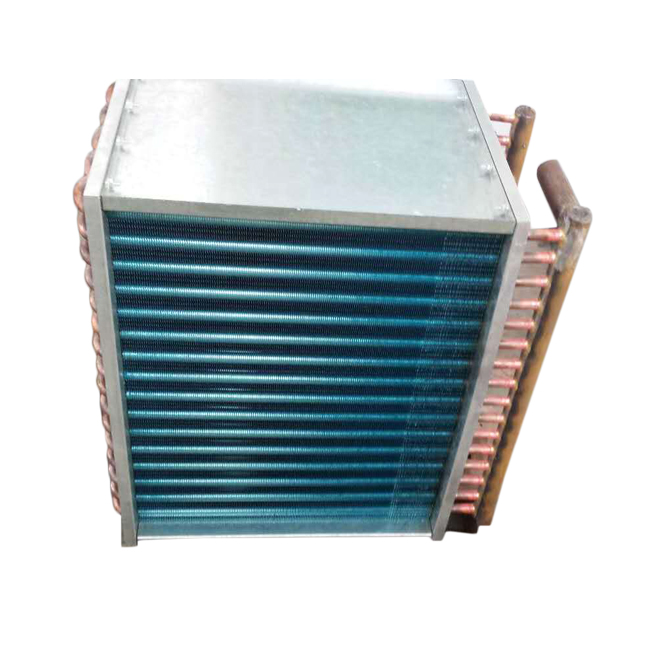

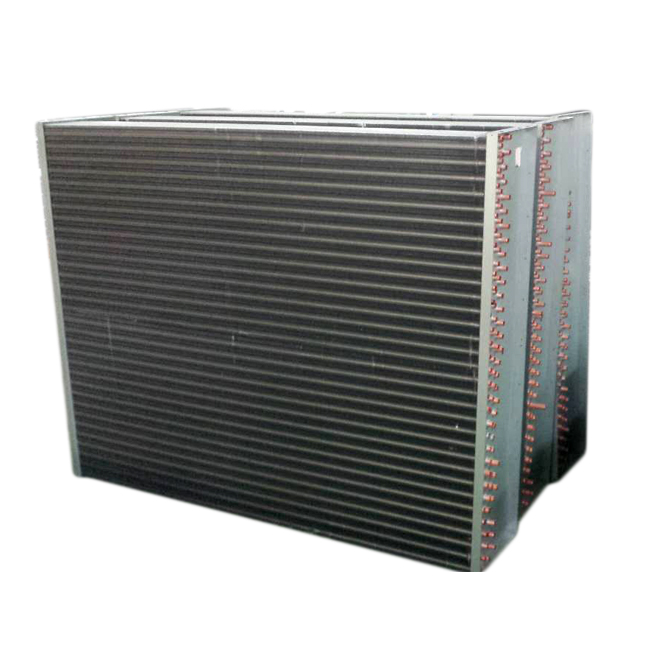

Freon Unit Cooler

Evaporator Coil/Unit Cooler Evaporator

In case you do not find the type or model in the website

We can customized according to your request.

Contact Now

Contact Now

- TEL:0086-21-35324169

- FAX:0086-21-35324166

- Email:sales@shenglintec.com

- WhatsApp:0086 13916147965

- Mob:0086 13916147965

Copper Tube Aluminum fin evaporator

Copper Tube Aluminum fin evaporators are designed and manufactured for applications ranging from residential to industrial. Various applications include process equipment,

HVAC, food, dehumidifying and other. Tube sizes range from 7mm to 15.88mm. Materials include copper, aluminum, stainless steel, and others. This product is brazed or welded depending on the material and application.

Specification:

Tube sizes range from 7mm to 15.88mm. Materials include copper, aluminum, stainless steel, and others. This product is brazed or welded depending on the material and application.Our Advantages:

1) Professional manufacturer, ROHS, BV, SGS, ISO

2) More than 10 years’ experiences of manufacturing. Cooperate with many famous brands: Midea, Gree, TCL, LG, Samsung, Hitachi, Panasonic etc.

3) Experienced technical staff. We have senior engineers and technicians more than 20 people with many years of experiences.

4) Three- step Quality control. Inspect the raw material, unfinished products and finished products.

5) Our products can be customized. We can produce for clients according to the sample or drawings.

6) Very competitive price with high quality products and perfect delivery date.

|

Item

|

Cooling coil Type

|

Operation medium

|

Operation pressure (MPa)

|

Application

|

| 1 | Φ16/Φ9.52/Φ12.7 Copper tube with aluminium fin | Cold/hot water | ≤1.6 | Used for combined air handling unit, fan coil etc air conditioning devices |

| 2 | Φ18/Φ20 Steel pipe winding with steel sheet | Steam | ≤0.2 | Used for combined air handling unit, fan coil etc air conditioning devices |

| 3 | Φ16/Φ9.52/Φ12.7 Copper tube with aluminium fin | Brine | ≤1.6 | Used for heat transfer in cold storage and all kinds of low temperature systems |

| 4 | Φ9.52/Φ7.94/Φ7 Copper tube with aluminium fin | Ethylene glycol | ≤1.6 | Used of energy recovery and low temperature system devices |

| 5 | Φ16 Copper tube with aluminium fin | Ice mud | ≤1.6 | Used for dry operation condition, fresh air dehumidification etc systems |

| 6 | Φ9.52/Φ7.94/Φ7 Copper tube with aluminium fin | R22 | ≤1.9 | Used for industry and commerce air conditioning system |

| 7 | Φ9.52/Φ7.94/Φ7 Copper tube with aluminium fin | R407C | ≤1.9 | Used for industry and commerce air conditioning system |

| 8 | Φ9.52/Φ7.94/Φ7 Copper tube with aluminium fin | R134a | ≤3.1 |

Used for vehicle and vessel etc transportation devices |

Mold of Copper tube&aluminum fin/copper fin

Mold of Stainless steel tube&aluminum fin/copper fin

| Fin Pattern | Copper Tube O.D.(mm) | Row Space(mm) | Hole Space(mm) |

Fin Thickness(mm) |

Fin Space(mm) | ||||

| Flat fin | Sine wave with blade fin | Smooth sine wave fin | Window fin | Sesamoid fin | |||||

| A | 7 | 12.7 | 21 | 0.105 | / | / | 1.3 | 1.3 | / |

| B | 7 | 13.2 | 17.6 | 0.105 | / | / | 1.3 | 1.3 | / |

| C | 7 | 12.7 | 20.4 | 0.105 | / | / | 1.3~1.8 | 1.3~1.8 | / |

| D | 7 | 12.7 | 19.05 | 0.105 | / | / | 1.3~1.8 | 1.3~1.8 | / |

| E | 7.94 | 15.88 | 25.4 | 0.105 | 1.8~3.0 | 1.8~3.0 | 1.8~3.0 | 1.8~3.0 | / |

| E | 7.94 | 19.05 | 22 | 0.105~0.13 | 1.4~3.0 | 1.4~3.0 | 1.4~3.0 | 1.4~3.0 | / |

| F | 9.52 | 22 | 25.4 | 0.105~0.15 | 1.6~3.2 | 1.6~3.2 | 1.6~3.2 | 1.6~3.2 | / |

| G | 9.52 | 22 | 25.4 | 0.18~0.4 | 3.5~6.35 | / | / | / | / |

| H | 9.52 | 21.65 | 25 | 0.105~0.18 | 1.6~3.2 | 1.6~3.2 | 1.6~3.2 | 1.6~3.2 | / |

| I | 9.52 | 21.65 | 25 | 0.15~0.24 | 3.2~6.35 | 3.2~6.35 | 3.2~6.35 | / | / |

| J | 12.75 | 27.5 | 31.75 |

0.115~0.15 |

1.5~3.5 | 1.5~3.5 | 1.5~3.5 | 1.5~3.5 | 1.6~3.2 |

| K | 15.88 | 33 | 38.1 | 0.115~0.15 | 1.5~4.0 | 1.5~4.0 | 1.5~4.0 | / | / |

| L | 15.88 | 34.64 | 40 | 0.115~0.15 | / | 2.6~3.5 | 2.6~3.5 | / | / |

Mold of Stainless steel tube&aluminum fin/copper fin

| Fin Pattern | Stainless steel Tube O.D.(mm) | Row Space(mm) | Hole Space(mm) |

Fin Thickness(mm) |

Fin Space(mm) | ||||

| Flat fin | Sine wave with blade fin | Smooth sine wave fin | Window fin | Sesamoid fin | |||||

| A | 9.52 | 22 | 25.4 | 0.105~0.15 | 1.6~3.2 | 1.6~3.2 | 1.6~3.2 | 1.6~3.2 | / |

| B | 9.52 | 16.5 | 19.05 | 0.105~0.115 | 1.4~2.5 | 1.4~2.5 | 1.4~2.5 | / | / |

| C | 12.75 | 27.5 | 31.75 |

0.115~0.15 |

1.5~3.5 | 1.5~3.5 | 1.5~3.5 | 1.5~3.5 | 1.6~3.2 |

| D | 15.88 | 33 | 38.1 | 0.115~0.15 | 1.5~4.0 | 1.5~4.0 | 1.5~4.0 | / |

/ |

Types of evaporators

Application:

Application:

+Newsmore

- 01 Feb,2024Dry Cooler D4-8x910 In Stock Is On Sale! Discount!

- 06 Sep,2023Pad Adiabatic Dry Cooler Trial Operation Before Shipment

- 06 Sep,2023828kW Adiabatic Cooling System Dry Cooler Loading

- 17 Aug,2022Flat Type Dry Cooler Finished For Canada Client

- 06 Sep,20231061kW dry cooler loading for USA client

- 31 Mar,2021Peru client Install Shenglin Adiabatic Dry Cooler At Site