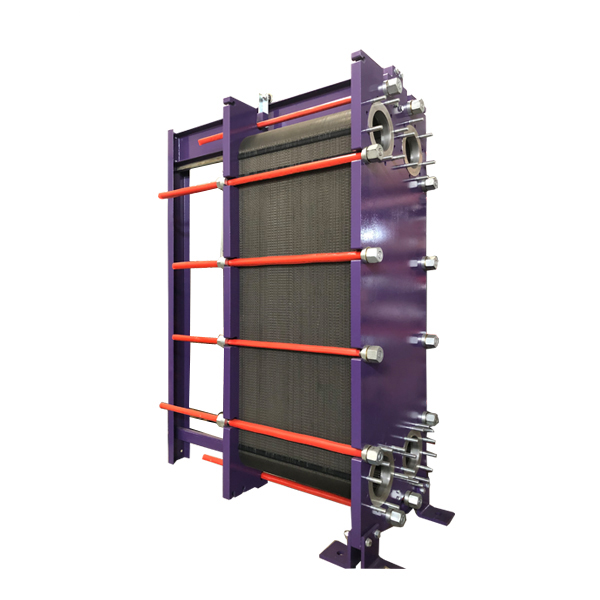

Plate Heat Exchanger

Copper Brazed Plate Heat Exchanger

In case you do not find the type or model in the website

We can customized according to your request.

Contact Now

Contact Now

- TEL:0086-21-35324169

- FAX:0086-21-35324166

- Email:sales@shenglintec.com

- WhatsApp:0086 13916147965

- Mob:0086 13916147965

1.Compact structure: adopt thin stainless steel, high heat transfer factors.

2.Reliability: adopt 316L and copper as well as high quality brazing works. Endure high pressure and temperature. Long life and no

maintenance need.

3.Reduce water require: with the high heat transfer efficiency, only needs 1/3 water usage compare to shell and tube exchanger

under same condition

4.Lightly: Only 20-30% weight compare to shell and tube heat exchanger and reduce the logistics cost.

5.Low fouling factors: high disorderly flow lower the fouling condition, reduce the maintain.

6.With distributor: increase the refrigerant evaporating efficiency and reduce the risks by using distributor to force the

refrigerant flow direction.

|

B

(mm) |

B1

(mm) |

D

(mm) |

D1

(mm) |

A

(mm) |

Volume

(L) |

area

(m²) |

weight

(kg) |

distributor

|

capacity

(KW) |

|

391.4

|

397.2

|

397.2

|

163.7

|

11+2.3n

|

0.16

|

0.11

|

6.5+0.42n

|

Q

|

60~200

|

|

391.4

|

397.2

|

397.2

|

163.7

|

11+2.2n

|

0.16

|

0.11

|

6.5+0.33n

|

Q

|

50~250

|

|

599

|

628

|

628

|

232

|

13+2.85n

|

0.4

|

0.21

|

13+0.82n

|

Q

|

150~450

|

|

Mold

|

clamp size

|

max width

|

max height

|

max length

|

interface size

|

max number of chip

|

max flow

|

|

BB30H

|

N(2.4+X)

|

180

|

490

|

680

|

32

|

90

|

13

|

|

BB60B

|

N(2.0+X)

|

320

|

930

|

1200

|

60

|

250

|

36

|

|

BB60H

|

N(3.0+X)

|

320

|

930

|

1200

|

60

|

203

|

36

|

|

BB65T

|

N(4.0+X)

|

410

|

700

|

1400

|

65

|

130

|

72

|

|

BB100B

|

N(3.95+X)

|

470

|

1069

|

1600

|

100

|

278

|

140

|

|

BB100H

|

N(3.95+X)

|

470

|

1069

|

1600

|

100

|

180

|

140

|

|

BB150B

|

N(2.5+X)

|

610

|

1815

|

3000

|

150

|

600

|

360

|

|

BB150T

|

N(3.95+X)

|

610

|

1815

|

3000

|

150

|

450

|

360

|

|

BB200T

|

N(2.5+X)

|

800

|

1435

|

2700

|

295

|

285

|

520

|

|

BB200H

|

N(4.0+X)

|

780

|

2150

|

3000

|

200

|

420

|

600

|

|

BB250B

|

N(2.5+X)

|

920

|

2900

|

3300

|

250

|

500

|

900

|

|

BB300B

|

N(3.5+X)

|

1100

|

2415

|

3360

|

300

|

300

|

997

|

Typical applications:

1. Heating: Boilers, Heat Pumps, District Heating, Domestic Water, Radiant, Solar.

2. Air Conditioning: Chillers, Absorption Chillers, Condensers.

3. Refrigeration: Transport, Supermarkets.

4. Industrial

5. Manufacturing

6. Process

1. Heating: Boilers, Heat Pumps, District Heating, Domestic Water, Radiant, Solar.

2. Air Conditioning: Chillers, Absorption Chillers, Condensers.

3. Refrigeration: Transport, Supermarkets.

4. Industrial

5. Manufacturing

6. Process

próximo:ninguno

+Newsmore

- 01 Feb,2024Dry Cooler D4-8x910 In Stock Is On Sale! Discount!

- 06 Sep,2023Pad Adiabatic Dry Cooler Trial Operation Before Shipment

- 06 Sep,2023828kW Adiabatic Cooling System Dry Cooler Loading

- 17 Aug,2022Flat Type Dry Cooler Finished For Canada Client

- 06 Sep,20231061kW dry cooler loading for USA client

- 31 Mar,2021Peru client Install Shenglin Adiabatic Dry Cooler At Site