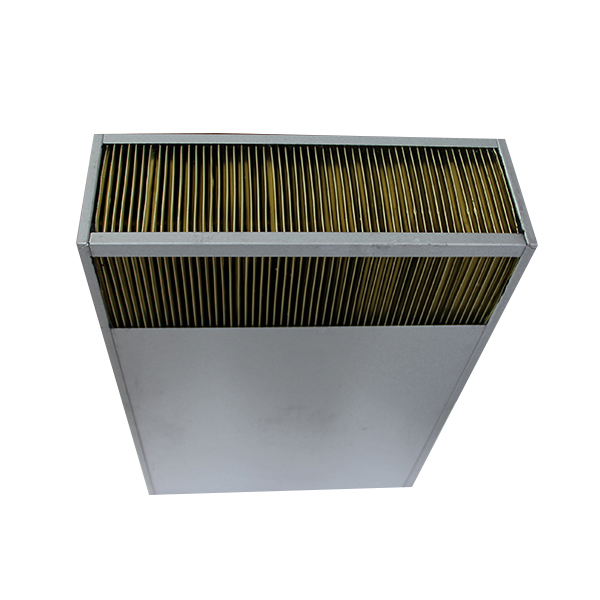

Cross Flow Heat Exchanger

Cross Flow Heat Exchanger/Cross-Flow Plate Heat Exchanger Pri

In case you do not find the type or model in the website

We can customized according to your request.

Contact Now

Contact Now

- TEL:0086-21-35324169

- FAX:0086-21-35324166

- Email:sales@shenglintec.com

- WhatsApp:0086 13916147965

- Mob:0086 13916147965

1. Adopt antiseptic hydrophilic aluminium foil, resistant to corrosion, with long service life.

2. Apply to special occasions of epoxy resin aluminum foil, corrosion resistance stronger.

3. Many size hrat exchanger core ( plate distance 2.5 ~ 10㎜ ) for your choice.

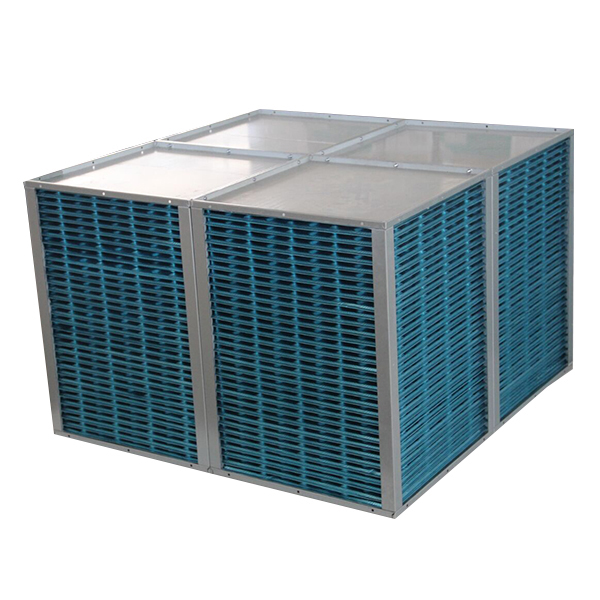

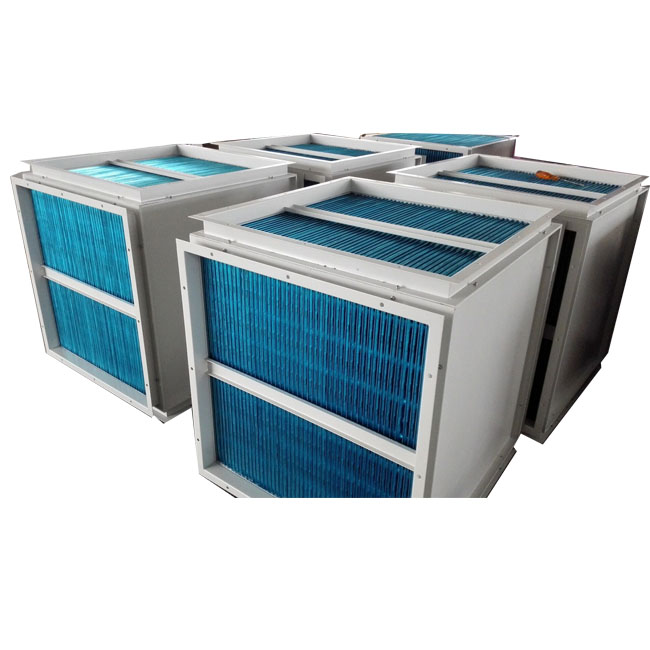

4. Module structure, any sine can be praided, no running components, low maintenance cost.

5. Compact struxture, small volume, suitable for various occasions.

Production Technology

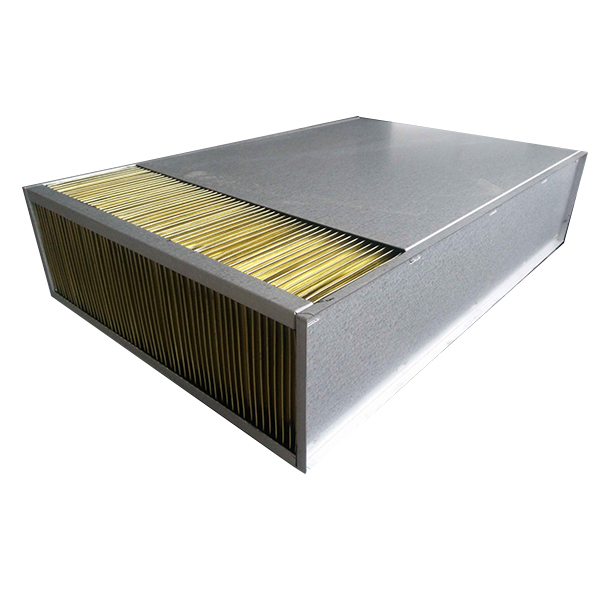

1. The surface of heat exchanger core was processed with spiral wave heat transfer enhancement techniques, increased the 10% heat transfer area.

2. Convex and concave air channel, ensure the strength and tightness of heat exchanger core, could bear high pressure.

3. Cross air channel, double folding process of the face side edges,which is equal to 5 times material thickness, ensure the high intensity and tightness.

4. All joints are airproofed by airproof glue, ensured that the heat exchanger has excellent air tightness.

4. All joints are airproofed by airproof glue, ensured that the heat exchanger has excellent air tightness.

|

|

|

|

|

| The antiseptic galvanized sheet framework, failure-free operation | Spiral layer edges heat transfer enhancement techniques, ensure the intensity and tightness | Five layer edges process of the face side edges, ensure the high intensity and tightness | Plate joint seal processing, Ripple bite edge guarantee air tightness | Plate distance 2.5~10.0mm |

Remark: The different material and thickness of framework are able to choose from (Such as: Galavanized sheet, Aluminum zinc coated steel sheet, Aluminium sheet, Painting steel plate, Painting galvanized sheet, Stainless steel and other anticorrosive material), the connecting format of framework has screw, buckle, flange and so on.

Air to air heat exchanger core are widely used for different industry air exchanger, heat recovery, cooling or heating and dehumidification. Such as in HVAC, Telecom, Power Supply, Textile Industry, Automobile, Food Industry, Agriculture, Animal husbandry, Tobacco barn, Drying industry, Welding industry, Boiler Industry and so on.

anterior:ninguno

Related Product

+Newsmore

- 01 Feb,2024Dry Cooler D4-8x910 In Stock Is On Sale! Discount!

- 06 Sep,2023Pad Adiabatic Dry Cooler Trial Operation Before Shipment

- 06 Sep,2023828kW Adiabatic Cooling System Dry Cooler Loading

- 17 Aug,2022Flat Type Dry Cooler Finished For Canada Client

- 06 Sep,20231061kW dry cooler loading for USA client

- 31 Mar,2021Peru client Install Shenglin Adiabatic Dry Cooler At Site