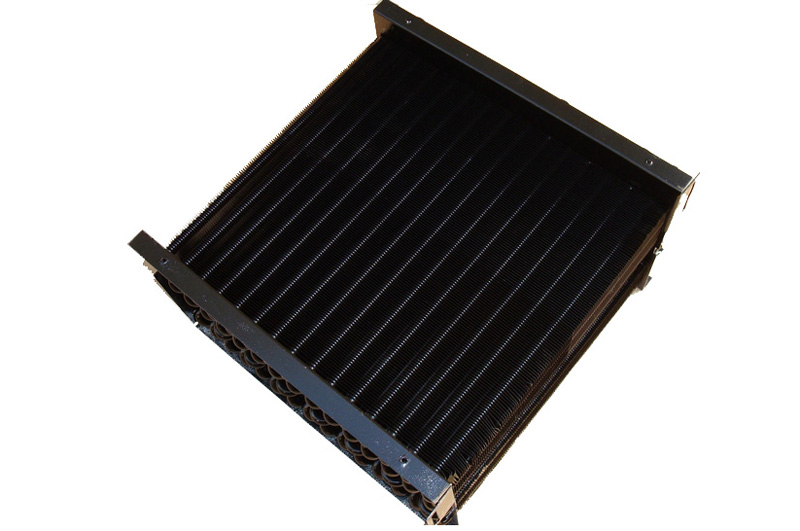

Fin Evaporator

Cold room Evaporator

In case you do not find the type or model in the website

We can customized according to your request.

Contact Now

Contact Now

- TEL:0086-21-35324169

- FAX:0086-21-35324166

- Email:sales@shenglintec.com

- WhatsApp:0086 13916147965

- Mob:0086 13916147965

Cold room Evaporators:

Cold room Evaporators are designed and manufactured for cold room. Usually produce our condenser and evaporator according to the client`s drawing. Design service is avaliable.

Specification:

Tube sizes range from 7mm to 15.88mm. Materials include copper, aluminum, stainless steel, and others. This product is brazed or welded depending on the material and application.

Product Features:

1 Material: copper, aluminium, galvanized, Stainless steel plate.

2 Copper pipe: diameterΦ7, Φ7.94, Φ9.52, Φ12.7, Φ15.8mm, etc. inner grooved or smooth tube.

3 Aluminium foil: hydrophilic or bare

4 Fin type: louver fin, flat fin, corrugated fin

5 Pitch of fins: can be adjusted between 1.8-5.8mm

6 Pitch of holes and pitch of rows: 25x21.65mm, 25.4x22mm, 21x12.7mm, 19.5x12.7mm, 31.75x27.5mm, equilateral triangle arrangement.

7 Suitable for R134a, R22, R404a, R407c refrigerant and so on.

Our Advantages:

1) Professional manufacturer, RHOS, BV, SGS

2) More than 10 years’ experiences of manufacturing. Cooperate with many famous brands: Midea, Gree, TCL, LG, Samsung, Hitachi, Panasonic etc.

3) Experienced technical staff. We have senior engineers and technicians more than 20 people with many years of experiences.

4) Three- step Quality control. Inspect the raw material, unfinished products and finished products.

5) Our products can be customized. We can produce for clients according to the sample or drawings.

6) Very competitive price with high quality products and perfect delivery date.

Cold room Evaporators are designed and manufactured for cold room. Usually produce our condenser and evaporator according to the client`s drawing. Design service is avaliable.

Specification:

Tube sizes range from 7mm to 15.88mm. Materials include copper, aluminum, stainless steel, and others. This product is brazed or welded depending on the material and application.

Product Features:

1 Material: copper, aluminium, galvanized, Stainless steel plate.

2 Copper pipe: diameterΦ7, Φ7.94, Φ9.52, Φ12.7, Φ15.8mm, etc. inner grooved or smooth tube.

3 Aluminium foil: hydrophilic or bare

4 Fin type: louver fin, flat fin, corrugated fin

5 Pitch of fins: can be adjusted between 1.8-5.8mm

6 Pitch of holes and pitch of rows: 25x21.65mm, 25.4x22mm, 21x12.7mm, 19.5x12.7mm, 31.75x27.5mm, equilateral triangle arrangement.

7 Suitable for R134a, R22, R404a, R407c refrigerant and so on.

Our Advantages:

1) Professional manufacturer, RHOS, BV, SGS

2) More than 10 years’ experiences of manufacturing. Cooperate with many famous brands: Midea, Gree, TCL, LG, Samsung, Hitachi, Panasonic etc.

3) Experienced technical staff. We have senior engineers and technicians more than 20 people with many years of experiences.

4) Three- step Quality control. Inspect the raw material, unfinished products and finished products.

5) Our products can be customized. We can produce for clients according to the sample or drawings.

6) Very competitive price with high quality products and perfect delivery date.

Main Technical Parameters of DD-type Low Noise High Efficiency Air Coolers

Main Technical Parameters of DJ-type Low Noise High Efficiency Air Coolers

| Type |

Refrigerating Capacity |

Cooling Area (mm) |

Pitch of Fins (mm) |

Air cooler | Electric pipe | ||||||||

| Qty. | Dia | Wind Rate |

Wind Pressure |

Power |

Voltage Water Flow |

KW×pcs |

Water drain (kw) |

Voltage Water Flow |

|||||

| DD-1.4/7 | 1400(1200) | 8.4 | 6 | 1 | φ300 | 1700 | 140 | 80 | 380 | 0.5×2 | 0.5 | 380 | |

| DD-2.35/12 | 2350(2000) | 11.5 | 6 | 2 | φ300 | 2×1700 | 140 | 2×80 | 380 | 0.9×2 | 0.9 | 380 | |

| DD-3.0/15 | 3000(2600) | 15.2 | 6 | 2 | φ300 | 2×1700 | 140 | 2×80 | 380 | 0.9×2 | 0.9 | 380 | |

| DD-4.0/22 | 4000(3450) | 22.8 | 6 | 2 | φ350 | 2×3200 | 90 | 2×120 | 380 | 1.2×2 | 1.2 | 380 | |

| DD-6.0/30 | 6000(5150) | 31.7 | 6 | 2 | φ350 | 2×3200 | 90 | 2×200 | 380 | 1.5×2 | 1.5 | 380 | |

| DD-8.0/40 | 8000(6900) | 43.4 | 6 | 2 | φ400 | 2×4800 | 120 | 2×250 | 380 | 1.6×2 | 1.6 | 380 | |

| DD-12.0/60 | 12000(10300) | 59.0 | 6 | 2 | φ400 | 2×4800 | 120 | 2×250 | 380 | 1.8×2 | 1.8 | 380 | |

| DD-16.0/80 | 16000(13750) | 87.8 | 6 | 2 | φ450 | 2×6600 | 160 | 2×550 | 380 | 1.6×5 | 1.6 | 380 | |

| DD-20.0/100 | 20000(17200) | 106.7 | 6 | 3 | φ450 | 3×6600 | 160 | 3×550 | 380 | 1.8×5 | 1.8 | 380 | |

| DD-24.0/120 | 24000(20650) | 131.5 | 6 | 3 | φ450 | 3×6600 | 160 | 3×550 | 380 | 2.4×5 | 2.4 | 380 | |

| DD-28.0/140 | 28000(24100) | 153.5 | 6 | 4 | φ450 | 4×6600 | 160 | 4×550 | 380 | 3×5 | 3.0 | 380 | |

| DD-32.1/160 | 32100(27600) | 175 | 6 | 4 | φ500 | 4×9900 | 170 | 4×740 | 380 | 3.2×5 | 3.2 | 380 | |

| DD-37.4/200 | 37400(32200) | 208 | 6 | 2 | φ600 | 2×10000 | 200 | 2×1100 | 380 | 2.7×8 | 2.7 | 380 | |

| DD-46.8/250 | 46800(40300) | 259 | 6 | 3 | φ600 | 3×10000 | 200 | 3×1100 | 380 | 3.3×8 | 3.3 | 380 | |

| DD-56.2/310 | 56200(48300) | 310.5 | 6 | 3 | φ600 | 3×12000 | 200 | 3×2200 | 380 | 3.5×8 | 3.5 | 380 | |

Main Technical Parameters of DJ-type Low Noise High Efficiency Air Coolers

| Type |

Refrigerating Capacity |

Cooling Area (mm) |

Pitch of Fins (mm) |

Air cooler | Electric pipe | ||||||||

| Qty. | Dia | Wind Rate |

Wind Pressure |

Power |

Voltage Water Flow |

KW×pcs |

Water drain (kw) |

Voltage Water Flow |

|||||

| DJ-13.2/8 | 1320(1150) | 7.95 | 9 | 2 | φ300 | 2×1700 | 140 | 2×80 | 380 | 0.9×2 | 0.9 | 380 | |

| DJ-2.3/15 | 2300(2000) | 15.9 | 9 | 2 | φ350 | 2×3200 | 90 | 2×120 | 380 | 1.2×2 | 1.2 | 380 | |

| DJ-4.0/20 | 4000(3450) | 21.8 | 9 | 2 | φ350 | 2×3200 | 90 | 2×200 | 380 | 1.5×2 | 1.5 | 380 | |

| DJ-5.1/30 | 5100(4400) | 30 | 9 | 2 | φ400 | 2×4800 | 120 | 2×250 | 380 | 1.6×2 | 1.6 | 380 | |

| DJ-7.8/40 | 7800(6700) | 40.2 | 9 | 2 | φ400 | 2×4800 | 120 | 2×250 | 380 | 1.8×2 | 1.8 | 380 | |

| DJ-9.8/55 | 9800(8400) | 60.3 | 9 | 2 | φ450 | 2×6600 | 160 | 2×550 | 380 | 1.6×5 | 1.6 | 380 | |

| DJ-12.8/70 | 12800(11000) | 73.3 | 9 | 3 | φ450 | 3×6600 | 160 | 3×550 | 380 | 1.8×5 | 1.8 | 380 | |

| DJ-15.7/85 | 15700(13500) | 90.4 | 9 | 3 | φ450 | 3×6600 | 160 | 3×550 | 380 | 2.4×5 | 2.4 | 380 | |

| DJ-18.8/100 | 18800(16160) | 105.3 | 9 | 4 | φ450 | 4×6600 | 160 | 4×550 | 380 | 3×5 | 3.0 | 380 | |

| DJ-21.6/115 | 21600(18600) | 120.6 | 9 | 4 | φ500 | 4×9900 | 170 | 4×740 | 380 | 3.2×5 | 3.2 | 380 | |

| DJ-29.3/140 | 23900(26600) | 142.7 | 9 | 2 | φ600 | 2×10000 | 420 | 2×1100 | 380 | 2.7×8 | 2.7 | 380 | |

| DJ-29.0/170 | 29000(24900) | 178 | 9 | 3 | φ600 | 3×10000 | 420 | 3×1100 | 380 | 3.3×8 | 3.3 | 380 | |

| DJ-35.9/210 | 35900(30900) | 209 | 9 | 3 | φ600 | 3×12000 | 420 | 3×2200 | 380 | 3.5×8 | 3.5 |

380 |

|

Application:

1.Used for combined air handling unit, fan coil etc air conditioning devices

2.Used for heat transfer in cold storage and all kinds of low temperature systems

3.Used of energy recovery and low temperature system devices

4.Used for dry operation condition, fresh air dehumidification etc systems

5.Used for industry and commerce air conditioning system

6.Used for vehicle and vessel etc transportation devices

1.Used for combined air handling unit, fan coil etc air conditioning devices

2.Used for heat transfer in cold storage and all kinds of low temperature systems

3.Used of energy recovery and low temperature system devices

4.Used for dry operation condition, fresh air dehumidification etc systems

5.Used for industry and commerce air conditioning system

6.Used for vehicle and vessel etc transportation devices

Previous:Water Dispenser Evaporator

+Newsmore

- 11 Apr,2020Shenglin dry cooler`s installation at local site(solar system

- 11 Apr,2020Return to work

- 17 Jul,2019INVITATION-Bangkok RHVAC 2019

- 27 Feb,2019Non-standard customization condensing unit finished!

- 27 Feb,2019Low temperature chiller commissioning in Malaysia

- 27 Feb,2019Shenglin service team`s commissioning in Jordan