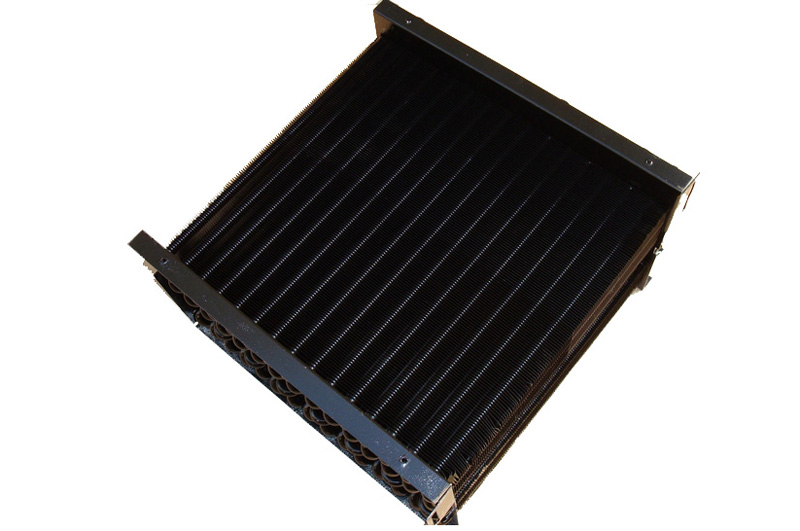

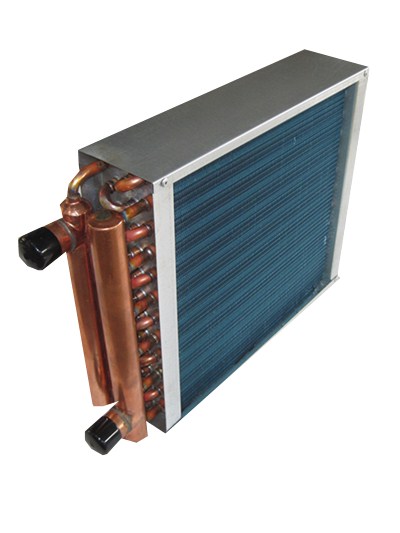

Fin Evaporator

Evaporator for fan coil unit

We're here to help

Easy ways to get the answers you need.

Contact Now

Contact Now

- TEL:0086-21-35324169

- FAX:0086-21-35324166

- Email:sales@shenglintec.com

Specifications

1. Evaporator Use for FCU

2. Customerized

3. Work Pressure:0.2~3.1MPa

4. Fin space:1.2~3.5mm

5. Tube Diameter:7, 7.94, 9.52, 12.7,15.88 etc.

Product Features:

1 Material: copper, aluminium, galvanized, Stainless steel plate.

2 Copper pipe: diameterΦ7, Φ7.94, Φ9.52, Φ12.7, Φ15.8mm, etc. inner grooved or smooth tube.

3 Aluminium foil: hydrophilic or bare

4 Fin type: louver fin, flat fin, corrugated fin

5 Pitch of fins: can be adjusted between 1.8-5.8mm

6 Pitch of holes and pitch of rows: 25x21.65mm, 25.4x22mm, 21x12.7mm, 19.5x12.7mm, 31.75x27.5mm, equilateral triangle arrangement.

7 Suitable for R134a, R22, R404a, R407c refrigerant and so on.

Our Advantages:

1) Professional manufacturer, ROHS, BV, SGS, ISO

2) More than 10 years’ experiences of manufacturing. Cooperate with many famous brands: Midea, Gree, TCL, LG, Samsung, Hitachi, Panasonic etc.

3) Experienced technical staff. We have senior engineers and technicians more than 20 people with many years of experiences.

4) Three- step Quality control. Inspect the raw material, unfinished products and finished products.

5) Our products can be customized. We can produce for clients according to the sample or drawings.

6) Very competitive price with high quality products and perfect delivery date.

1. Evaporator Use for FCU

2. Customerized

3. Work Pressure:0.2~3.1MPa

4. Fin space:1.2~3.5mm

5. Tube Diameter:7, 7.94, 9.52, 12.7,15.88 etc.

Product Features:

1 Material: copper, aluminium, galvanized, Stainless steel plate.

2 Copper pipe: diameterΦ7, Φ7.94, Φ9.52, Φ12.7, Φ15.8mm, etc. inner grooved or smooth tube.

3 Aluminium foil: hydrophilic or bare

4 Fin type: louver fin, flat fin, corrugated fin

5 Pitch of fins: can be adjusted between 1.8-5.8mm

6 Pitch of holes and pitch of rows: 25x21.65mm, 25.4x22mm, 21x12.7mm, 19.5x12.7mm, 31.75x27.5mm, equilateral triangle arrangement.

7 Suitable for R134a, R22, R404a, R407c refrigerant and so on.

Our Advantages:

1) Professional manufacturer, ROHS, BV, SGS, ISO

2) More than 10 years’ experiences of manufacturing. Cooperate with many famous brands: Midea, Gree, TCL, LG, Samsung, Hitachi, Panasonic etc.

3) Experienced technical staff. We have senior engineers and technicians more than 20 people with many years of experiences.

4) Three- step Quality control. Inspect the raw material, unfinished products and finished products.

5) Our products can be customized. We can produce for clients according to the sample or drawings.

6) Very competitive price with high quality products and perfect delivery date.

|

Item

|

Cooling coil Type

|

Operation medium

|

Operation pressure (MPa)

|

Application

|

| 1 | Φ16/Φ9.52/Φ12.7 Copper tube with aluminium fin | Cold/hot water | ≤1.6 | Used for combined air handling unit, fan coil etc air conditioning devices |

| 2 | Φ18/Φ20 Steel pipe winding with steel sheet | Steam | ≤0.2 | Used for combined air handling unit, fan coil etc air conditioning devices |

| 3 | Φ16/Φ9.52/Φ12.7 Copper tube with aluminium fin | Brine | ≤1.6 | Used for heat transfer in cold storage and all kinds of low temperature systems |

| 4 | Φ9.52/Φ7.94/Φ7 Copper tube with aluminium fin | Ethylene glycol | ≤1.6 | Used of energy recovery and low temperature system devices |

| 5 | Φ16 Copper tube with aluminium fin | Ice mud | ≤1.6 | Used for dry operation condition, fresh air dehumidification etc systems |

| 6 | Φ9.52/Φ7.94/Φ7 Copper tube with aluminium fin | R22 | ≤1.9 | Used for industry and commerce air conditioning system |

| 7 | Φ9.52/Φ7.94/Φ7 Copper tube with aluminium fin | R407C | ≤1.9 | Used for industry and commerce air conditioning system |

| 8 | Φ9.52/Φ7.94/Φ7 Copper tube with aluminium fin | R134a | ≤3.1 |

Used for vehicle and vessel etc transportation devices |

Mold of Copper tube&aluminum fin/copper fin

Mold of Stainless steel tube&aluminum fin/copper fin

| Fin Pattern | Copper Tube O.D.(mm) | Row Space(mm) | Hole Space(mm) |

Fin Thickness(mm) |

Fin Space(mm) | ||||

| Flat fin | Sine wave with blade fin | Smooth sine wave fin | Window fin | Sesamoid fin | |||||

| A | 7 | 12.7 | 21 | 0.105 | / | / | 1.3 | 1.3 | / |

| B | 7 | 13.2 | 17.6 | 0.105 | / | / | 1.3 | 1.3 | / |

| C | 7 | 12.7 | 20.4 | 0.105 | / | / | 1.3~1.8 | 1.3~1.8 | / |

| D | 7 | 12.7 | 19.05 | 0.105 | / | / | 1.3~1.8 | 1.3~1.8 | / |

| E | 7.94 | 15.88 | 25.4 | 0.105 | 1.8~3.0 | 1.8~3.0 | 1.8~3.0 | 1.8~3.0 | / |

| E | 7.94 | 19.05 | 22 | 0.105~0.13 | 1.4~3.0 | 1.4~3.0 | 1.4~3.0 | 1.4~3.0 | / |

| F | 9.52 | 22 | 25.4 | 0.105~0.15 | 1.6~3.2 | 1.6~3.2 | 1.6~3.2 | 1.6~3.2 | / |

| G | 9.52 | 22 | 25.4 | 0.18~0.4 | 3.5~6.35 | / | / | / | / |

| H | 9.52 | 21.65 | 25 | 0.105~0.18 | 1.6~3.2 | 1.6~3.2 | 1.6~3.2 | 1.6~3.2 | / |

| I | 9.52 | 21.65 | 25 | 0.15~0.24 | 3.2~6.35 | 3.2~6.35 | 3.2~6.35 | / | / |

| J | 12.75 | 27.5 | 31.75 |

0.115~0.15 |

1.5~3.5 | 1.5~3.5 | 1.5~3.5 | 1.5~3.5 | 1.6~3.2 |

| K | 15.88 | 33 | 38.1 | 0.115~0.15 | 1.5~4.0 | 1.5~4.0 | 1.5~4.0 | / | / |

| L | 15.88 | 34.64 | 40 | 0.115~0.15 | / | 2.6~3.5 | 2.6~3.5 | / | / |

Mold of Stainless steel tube&aluminum fin/copper fin

| Fin Pattern | Stainless steel Tube O.D.(mm) | Row Space(mm) | Hole Space(mm) |

Fin Thickness(mm) |

Fin Space(mm) | ||||

| Flat fin | Sine wave with blade fin | Smooth sine wave fin | Window fin | Sesamoid fin | |||||

| A | 9.52 | 22 | 25.4 | 0.105~0.15 | 1.6~3.2 | 1.6~3.2 | 1.6~3.2 | 1.6~3.2 | / |

| B | 9.52 | 16.5 | 19.05 | 0.105~0.115 | 1.4~2.5 | 1.4~2.5 | 1.4~2.5 | / | / |

| C | 12.75 | 27.5 | 31.75 |

0.115~0.15 |

1.5~3.5 | 1.5~3.5 | 1.5~3.5 | 1.5~3.5 | 1.6~3.2 |

| D | 15.88 | 33 | 38.1 | 0.115~0.15 | 1.5~4.0 | 1.5~4.0 | 1.5~4.0 | / |

/ |

Application:

1.Used for combined air handling unit, fan coil etc air conditioning devices

2.Used for heat transfer in cold storage and all kinds of low temperature systems

3.Used of energy recovery and low temperature system devices

4.Used for dry operation condition, fresh air dehumidification etc systems

5.Used for industry and commerce air conditioning system

6.Used for vehicle and vessel etc transportation devices

Packing picture:

1.Used for combined air handling unit, fan coil etc air conditioning devices

2.Used for heat transfer in cold storage and all kinds of low temperature systems

3.Used of energy recovery and low temperature system devices

4.Used for dry operation condition, fresh air dehumidification etc systems

5.Used for industry and commerce air conditioning system

6.Used for vehicle and vessel etc transportation devices

Packing picture:

Get Price And Support

Please leave your telephone number or mobile phone nubmer for emergency contact, in case we can not reach you by mail.

anterior:Laser Evaporator

+Newsmore

- 01 Apr,2016Assembling evaporator to plastic body with Pakistan client. Professional fin evaporator manufacturer Shanghai Shenglin,

- 01 Apr,2016Australian client visited us last Saturday

- 02 Feb,2016Happy Chinese New Year!

- 06 Jan,2016Packaged rooftop units finished for Nigeria client

- 16 Dec,2015All stainless steel condenser and evaporator for Egypt client finished.

- 03 Sep,2015Free Cooling Precision AC Finished for Russian Client

- 03 Sep,2015North Korea inspect our precision air conditioner.

- 03 Sep,2015Air handing units finished for Iraq Client

- 21 Jan,2015CE Certification for Heat Pump