Unit cooler

Unit Cooler

We're here to help

Easy ways to get the answers you need.

Contact Now

Contact Now

- TEL:0086-21-35324169

- FAX:0086-21-35324166

- Email:sales@shenglintec.com

Product features

1 .Unit Cooler

2. simple structure,accurate and reliable operating system

2. simple structure,accurate and reliable operating system

3. Certificates:CE,RoHS,ISO9001:2000

4. energy-efficient,environmentally friendly.

5. medium and low temperature cooling equipment.

6. integral installation,anticollision,rainproof structure feature

7. hermetic design and anti-corrosion outer shell

8 . low noise, efficient , strong-wind fan motor ,avoidance of sunshine and raining effect

9. completely welded to ensure less leakage (below 3g/year)

10. smaller volume,easy installation

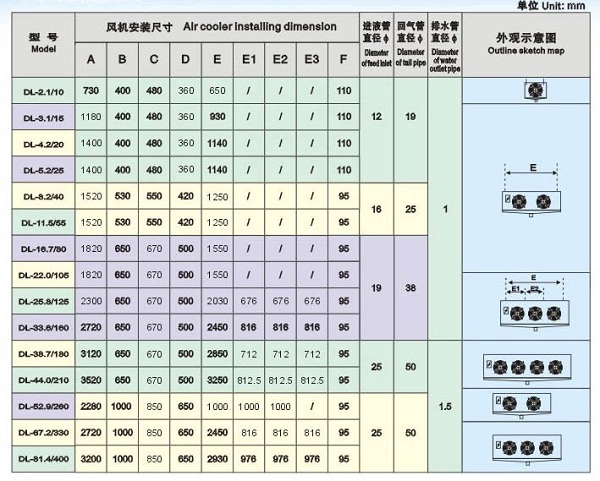

Main Technical Parameters of DD-type Low Noise High

Efficiency Unit Coolers

Main Technical Parameters of DJ-type Low Noise High Efficiency unit Coolers

Efficiency Unit Coolers

| Type |

Refrigerating Capacity |

Cooling Area (mm) |

Pitch of Fins (mm) |

unit cooler | Electric pipe | ||||||||

| Qty. | Dia | Wind Rate |

Wind Pressure |

Power |

Voltage Water Flow |

KW×pcs |

Water drain (kw) |

Voltage Water Flow |

|||||

| DD-1.4/7 | 1400(1200) | 8.4 | 6 | 1 | φ300 | 1700 | 140 | 80 | 380 | 0.5×2 | 0.5 | 380 | |

| DD-2.35/12 | 2350(2000) | 11.5 | 6 | 2 | φ300 | 2×1700 | 140 | 2×80 | 380 | 0.9×2 | 0.9 | 380 | |

| DD-3.0/15 | 3000(2600) | 15.2 | 6 | 2 | φ300 | 2×1700 | 140 | 2×80 | 380 | 0.9×2 | 0.9 | 380 | |

| DD-4.0/22 | 4000(3450) | 22.8 | 6 | 2 | φ350 | 2×3200 | 90 | 2×120 | 380 | 1.2×2 | 1.2 | 380 | |

| DD-6.0/30 | 6000(5150) | 31.7 | 6 | 2 | φ350 | 2×3200 | 90 | 2×200 | 380 | 1.5×2 | 1.5 | 380 | |

| DD-8.0/40 | 8000(6900) | 43.4 | 6 | 2 | φ400 | 2×4800 | 120 | 2×250 | 380 | 1.6×2 | 1.6 | 380 | |

| DD-12.0/60 | 12000(10300) | 59.0 | 6 | 2 | φ400 | 2×4800 | 120 | 2×250 | 380 | 1.8×2 | 1.8 | 380 | |

| DD-16.0/80 | 16000(13750) | 87.8 | 6 | 2 | φ450 | 2×6600 | 160 | 2×550 | 380 | 1.6×5 | 1.6 | 380 | |

| DD-20.0/100 | 20000(17200) | 106.7 | 6 | 3 | φ450 | 3×6600 | 160 | 3×550 | 380 | 1.8×5 | 1.8 | 380 | |

| DD-24.0/120 | 24000(20650) | 131.5 | 6 | 3 | φ450 | 3×6600 | 160 | 3×550 | 380 | 2.4×5 | 2.4 | 380 | |

| DD-28.0/140 | 28000(24100) | 153.5 | 6 | 4 | φ450 | 4×6600 | 160 | 4×550 | 380 | 3×5 | 3.0 | 380 | |

| DD-32.1/160 | 32100(27600) | 175 | 6 | 4 | φ500 | 4×9900 | 170 | 4×740 | 380 | 3.2×5 | 3.2 | 380 | |

| DD-37.4/200 | 37400(32200) | 208 | 6 | 2 | φ600 | 2×10000 | 200 | 2×1100 | 380 | 2.7×8 | 2.7 | 380 | |

| DD-46.8/250 | 46800(40300) | 259 | 6 | 3 | φ600 | 3×10000 | 200 | 3×1100 | 380 | 3.3×8 | 3.3 | 380 | |

| DD-56.2/310 | 56200(48300) | 310.5 | 6 | 3 | φ600 | 3×12000 | 200 | 3×2200 | 380 | 3.5×8 | 3.5 | 380 | |

Main Technical Parameters of DJ-type Low Noise High Efficiency unit Coolers

| Type |

Refrigerating Capacity |

Cooling Area (mm) |

Pitch of Fins (mm) |

unit cooler | Electric pipe | ||||||||

| Qty. | Dia | Wind Rate |

Wind Pressure |

Power |

Voltage Water Flow |

KW×pcs |

Water drain (kw) |

Voltage Water Flow |

|||||

| DJ-13.2/8 | 1320(1150) | 7.95 | 9 | 2 | φ300 | 2×1700 | 140 | 2×80 | 380 | 0.9×2 | 0.9 | 380 | |

| DJ-2.3/15 | 2300(2000) | 15.9 | 9 | 2 | φ350 | 2×3200 | 90 | 2×120 | 380 | 1.2×2 | 1.2 | 380 | |

| DJ-4.0/20 | 4000(3450) | 21.8 | 9 | 2 | φ350 | 2×3200 | 90 | 2×200 | 380 | 1.5×2 | 1.5 | 380 | |

| DJ-5.1/30 | 5100(4400) | 30 | 9 | 2 | φ400 | 2×4800 | 120 | 2×250 | 380 | 1.6×2 | 1.6 | 380 | |

| DJ-7.8/40 | 7800(6700) | 40.2 | 9 | 2 | φ400 | 2×4800 | 120 | 2×250 | 380 | 1.8×2 | 1.8 | 380 | |

| DJ-9.8/55 | 9800(8400) | 60.3 | 9 | 2 | φ450 | 2×6600 | 160 | 2×550 | 380 | 1.6×5 | 1.6 | 380 | |

| DJ-12.8/70 | 12800(11000) | 73.3 | 9 | 3 | φ450 | 3×6600 | 160 | 3×550 | 380 | 1.8×5 | 1.8 | 380 | |

| DJ-15.7/85 | 15700(13500) | 90.4 | 9 | 3 | φ450 | 3×6600 | 160 | 3×550 | 380 | 2.4×5 | 2.4 | 380 | |

| DJ-18.8/100 | 18800(16160) | 105.3 | 9 | 4 | φ450 | 4×6600 | 160 | 4×550 | 380 | 3×5 | 3.0 | 380 | |

| DJ-21.6/115 | 21600(18600) | 120.6 | 9 | 4 | φ500 | 4×9900 | 170 | 4×740 | 380 | 3.2×5 | 3.2 | 380 | |

| DJ-29.3/140 | 23900(26600) | 142.7 | 9 | 2 | φ600 | 2×10000 | 420 | 2×1100 | 380 | 2.7×8 | 2.7 | 380 | |

| DJ-29.0/170 | 29000(24900) | 178 | 9 | 3 | φ600 | 3×10000 | 420 | 3×1100 | 380 | 3.3×8 | 3.3 | 380 | |

| DJ-35.9/210 | 35900(30900) | 209 | 9 | 3 | φ600 | 3×12000 | 420 | 3×2200 | 380 | 3.5×8 | 3.5 | 380 | |

Water-melt-frost system is generally used in the large capacity cold air machine.

It is simple and reliable, has good effect in frost melting, less warehouse temperature rise in frost melting process, especially suitable for fast freezing refrigerating warehouse.

The disadvantage of this water-melt-frost system is that the water used to melt frost should not lower than 15℃,

so this kind of air cooler can’t be adopted by the area of low atmosphere temperature.

Various water-melt-frost unit coolers are provided for selection.

It is simple and reliable, has good effect in frost melting, less warehouse temperature rise in frost melting process, especially suitable for fast freezing refrigerating warehouse.

The disadvantage of this water-melt-frost system is that the water used to melt frost should not lower than 15℃,

so this kind of air cooler can’t be adopted by the area of low atmosphere temperature.

Various water-melt-frost unit coolers are provided for selection.

Get Price And Support

Please leave your telephone number or mobile phone nubmer for emergency contact, in case we can not reach you by mail.

anterior:ninguno

+Newsmore

- 01 Apr,2016Assembling evaporator to plastic body with Pakistan client. Professional fin evaporator manufacturer Shanghai Shenglin,

- 01 Apr,2016Australian client visited us last Saturday

- 02 Feb,2016Happy Chinese New Year!

- 06 Jan,2016Packaged rooftop units finished for Nigeria client

- 16 Dec,2015All stainless steel condenser and evaporator for Egypt client finished.

- 03 Sep,2015Free Cooling Precision AC Finished for Russian Client

- 03 Sep,2015North Korea inspect our precision air conditioner.

- 03 Sep,2015Air handing units finished for Iraq Client

- 21 Jan,2015CE Certification for Heat Pump